Sanitary fittings are crucial in the medical industry, serving as the unsung heroes in the battle against contamination and infection. These specialized components are designed with the utmost precision to ensure a sterile environment, which is essential in protecting patients and healthcare workers. Their ability to withstand rigorous cleaning protocols and their resistance to microbial growth make them indispensable in hospitals, laboratories, and any facility where hygiene is paramount. By maintaining the integrity of medical instruments and the purity of substances that come into contact with patients, sanitary fittings play a pivotal role in medical outcomes and patient safety.

Sterilization and Infection Control

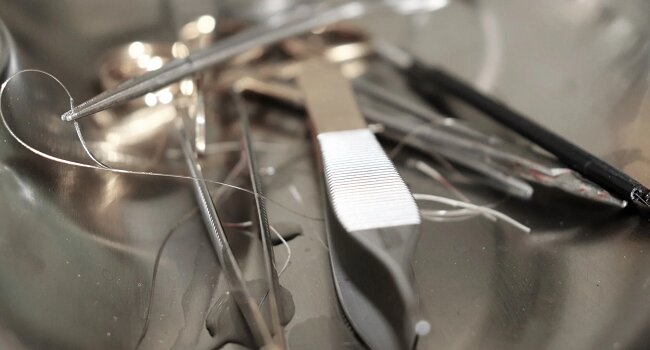

Sterilization and infection control are vital for patient safety. Sanitary clamp fittings play a key role by creating secure, leak-proof connections in medical equipment, preventing seepage and cross-contamination that can cause infections. With a design that allows for quick disassembly and reassembly, sanitary clamp fittings enable efficient cleaning and sterilization, essential in fast-paced medical settings. Their strong build can withstand high temperatures and harsh chemicals in autoclaves and cleaning processes.

This durability assures long-term reliability and sustains the performance of medical apparatus vital for life-saving procedures. The meticulous integration of sanitary clamp fittings into healthcare systems underscores their unyielding role in upholding standards for a clean and safe medical environment. Sanitary fittings play an integral role in infection control measures by inhibiting microbial growth and promoting sterilization.

Preventing Cross-Contamination

Preventing cross-contamination in clinical environments is a concern and a critical mandate. Using high-quality sanitary fittings significantly reduces the risk by providing an impervious barrier between different substances and processes. Materials such as stainless steel, commonly used in these fittings, are durable and non-reactive to a vast array of chemicals, minimizing potential reactions and leaching.

The smooth and non-porous surfaces of these fittings prevent the adherence and proliferation of bacteria and other pathogens. Furthermore, their design often incorporates quick-release mechanisms, allowing for rapid changes and cleaning, which is imperative in emergencies where time is of the essence. This attention to detail in the design and use of sanitary fittings fortifies the relentless fight against cross-contamination in medical care facilities.

Versatility and Compatibility

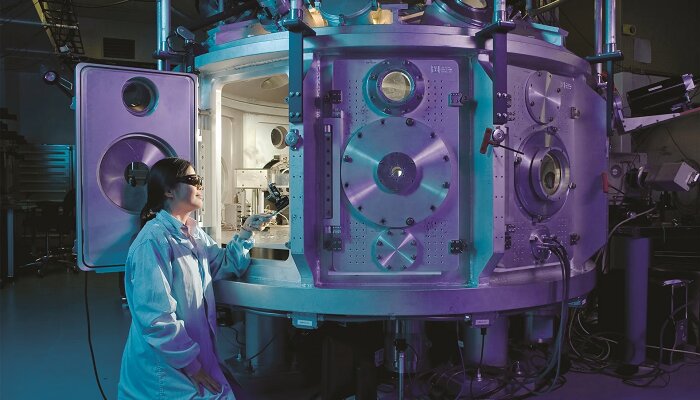

Sanitary fittings come in a wide range of sizes, shapes, and materials, making them highly versatile. They are designed to conform to various standards and specifications; these fittings are interoperable with a wide range of medical devices and equipment. This universal design minimizes equipment downtime and facilitates seamless integration into different systems, ensuring uninterrupted medical care.

Additionally, the modular nature of these fittings allows for easy upgrades or replacements, adapting quickly to technological advancements or procedural changes. Compatibility with diverse cleaning agents and sterilization methods also positions sanitary fittings as a versatile solution for maintaining a hygienic environment. Thus, their adaptability streamlines medical processes and reinforces a commitment to patient health and safety.

Economic Efficiency and Longevity

Using sanitary fittings not only bolsters medical safety but also proves economically viable. Their sturdy construction and reliability reduce the need for frequent replacements, saving on maintenance costs in the long run. Furthermore, their compatibility with numerous cleaning methods and agents lowers expenses associated with specialized equipment or products.

In contrast to other materials that may require replacement due to corrosion or wear, sanitary fittings are made from durable materials such as stainless steel, ensuring longevity and cost-effectiveness. This resilience also makes them an environmentally friendly choice, with a reduced ecological impact compared to disposable or short-lived alternatives.

Ensuring Patient Safety Through Stringent Hygiene Measures

The primary responsibility of any medical establishment is to provide safe conditions for patients undergoing treatment. Keeping these environments sanitary in a closed healthcare environment is especially challenging but crucial. Sanitary fittings must meet the industry’s rigid standards and be designed to promote meticulous hygiene protocols.

Touchless or sensor-activated fixtures further reduce the risk of contamination. This technology is vital in areas where infectious diseases are treated or can spread, such as in isolation rooms or emergency departments. Ensuring the patient environment is safe is a non-negotiable goal; the right sanitary fittings are integral to achieving it.

Complying with Hygiene Regulations

The medical industry is one of the most heavily regulated sectors and for a good reason. Compliance with rigid hygiene standards isn’t just about checking boxes; it’s about instilling a culture of safety and responsibility. Sanitary fittings, therefore, must be not only effective but also in line with current regulations.

Facility managers who invest in top-tier sanitary fittings and consistently enforce their use mitigate risks and set a benchmark for operational excellence. Awareness, training, and the proper infrastructure are foundations for a healthcare system that is both safe and efficient.

Sanitary fittings play a vital role in medical environments, impacting human welfare. As hospitals focus more on this aspect, they raise the standard of care to exceptional levels. It’s time to acknowledge these unsung heroes and give them the attention and investment they deserve. In saving lives, every detail matters.