The pharmaceutical technology landscape is evolving at a rapid pace. At the same time, healthcare data breaches have become alarmingly costly, averaging $10.93 million—more than in any other industry. This growing risk highlights why innovation in pharma must prioritize security and compliance alongside scientific breakthroughs.

Across the sector, companies are investing heavily in advanced technologies to enhance both research and manufacturing. Automation now plays a central role in overcoming challenges related to production, packaging, and distribution.

In 2024, AI-driven drug production has seen remarkable growth. Intelligent systems are improving both the quality of output and regulatory compliance. In this article, we examine the technologies reshaping pharmaceutical manufacturing and transforming the future of healthcare.

AI and Machine Learning in Drug Manufacturing

AI technology has become a cornerstone of modern pharmaceutical manufacturing. The pharma industry’s adoption of Industry 4.0 uses AI to build well-controlled, interconnected digital systems throughout its value chain.

AI for Predictive Maintenance in Production Lines

AI-powered predictive maintenance stands out as one of the most valuable applications in pharmaceutical manufacturing. Traditional maintenance follows fixed schedules without considering equipment condition. The AI approach analyzes live data from production equipment to spot potential failures before they happen. This brings clear benefits:

- Early problem detection cuts unplanned downtime

- Service only when needed reduces maintenance costs

- Timely fixes extend equipment life

- Better production efficiency and consistent quality

Novartis shows how this works in practice. The company’s IoT sensors keep watch over critical equipment and feed data to AI algorithms that predict when things might go wrong. Their system has cut downtime and boosted equipment effectiveness. The numbers tell the story – companies can expect a 10-15% boost in equipment effectiveness by using AI to predict and prevent key issues.

Machine Learning for Drug Candidate Screening

Machine learning has transformed the drug screening process. These tools can analyze massive datasets to find promising drug candidates, which cuts development time and costs.

The latest foundational chemistry models map millions of compounds by their structure and function. They match this data with results from tested molecules. These systems work like language prediction models – they learn chemistry’s basic rules through repeated iterations and can predict the next parts of molecular structures.

The results speak for themselves. Companies that use machine learning for screening get 2.5 times better performance in chemical compound activity models. They also work four times faster, cutting the time to find new leads from months to just weeks.

Challenges still exist. AI models need quality data to make accurate predictions. All the same, AI keeps driving big improvements in efficiency, quality, and breakthroughs across the pharmaceutical industry.

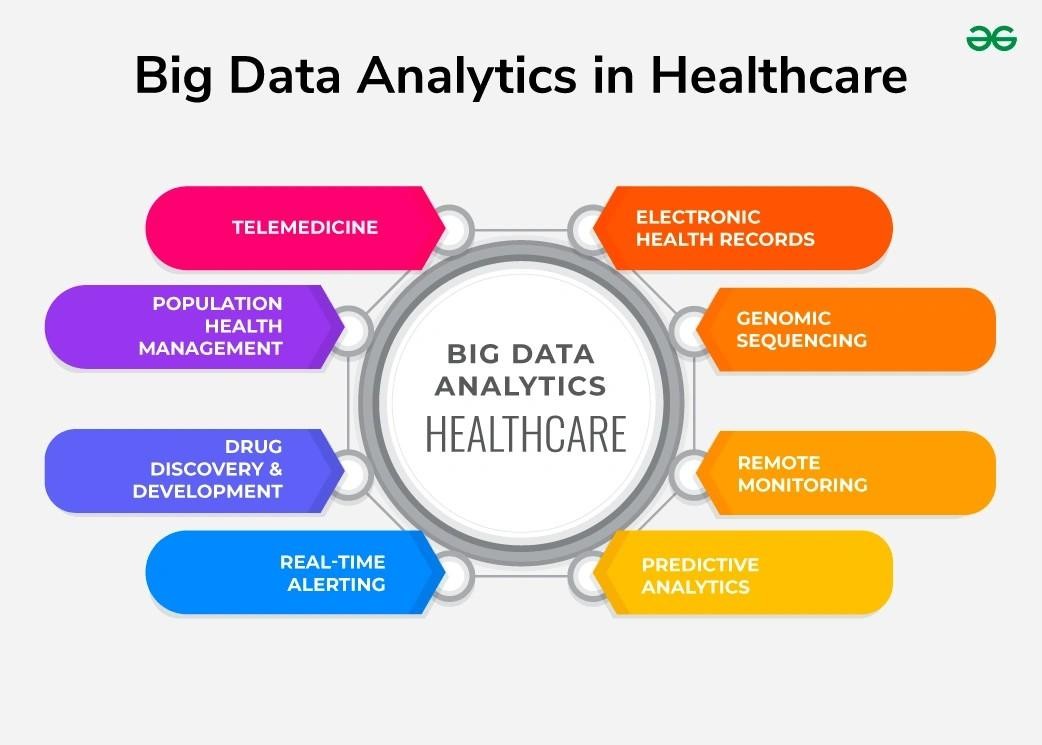

Big Data, Cloud, and Real-World Evidence

Data and analytics are now the foundations of pharmaceutical development and manufacturing. The combination of big data and cloud technology provides new insights throughout a drug’s lifecycle, from its original discovery to monitoring after market release.

Cloud-Based Collaboration in Clinical Trials

Cloud platforms have transformed how we manage clinical trials by bringing data together and making real-time teamwork possible. Companies that use these technologies see remarkable results – enrollment speeds up by 200% while costs drop by 50%.

Through collaboration with Google Cloud, Medable shows this trend by offering sponsors easier procurement and united billing while using advanced cloud infrastructure. These decentralized trials bring substantial financial rewards—five to thirteen times return on investment for Phase II and Phase III trials respectively.

Real-World Data from Wearables and EHRs

The FDA now recognizes Real-World Evidence (RWE) more in their regulatory decisions. About 85% of FDA-approved new drug and biologics license applications include some form of RWE. Wearable devices collect patient data continuously outside controlled settings. This reduces the burden on participants and lets doctors monitor them remotely. The benefits include:

- Data collection happens all the time instead of just during visits

- Information gathering becomes more objective with less recall bias

- AI helps recognize patterns and predict risks

- Early detection of possible adverse events

Data Lakes for Preclinical and Post-Market Analysis

Clinical data lakehouses combine what’s best about data lakes and warehouses. Organizations can store large amounts of structured and unstructured information while keeping it easy to analyze. This setup helps AI-powered clinical trials by combining different data streams naturally, from patient records to sensor data.

Operational Analytics for Manufacturing Performance

Analytics in pharmaceutical manufacturing leads to major improvements in how companies operate. Industry experts say advanced analytics can “affect net impact by at least 10 percent from both top and bottom lines.”

Tools like OEE software help track equipment performance in real time, enabling manufacturers to spot inefficiencies, reduce downtime, and boost overall productivity. Sensors that monitor equipment conditions also help predict potential failures before they stop production.

Blockchain and Cybersecurity in Pharma Supply Chains

Reliable supply chains are the life-blood of modern pharmaceutical technology. These chains now face unprecedented challenges from counterfeit products and digital threats. Companies are adopting innovative solutions faster to maintain integrity throughout the manufacturing and distribution process.

Blockchain for Drug Traceability under DSCSA

The Drug Supply Chain Security Act (DSCSA) requires an interoperable electronic system to identify and trace prescription drugs at the package level. Blockchain technology has become a viable solution that deals with the pharmaceutical industry’s biggest problems.

Blockchain’s distributed ledger creates an unchangeable record of every transaction. The MediLedger network, with its 24 major pharmaceutical companies, showed blockchain’s effectiveness in verifying drug returns. UCLA’s BRUINchain pilot achieved a perfect success rate for scanning, expiration detection, and counterfeit identification.

Cybersecurity Risks in Connected Pharma Devices

Connected devices in pharmaceutical manufacturing create critical vulnerabilities without proper protection. Operations environments don’t deal very well with security. These include programmable logic controllers and distributed control systems that focus on functionality rather than security.

Manufacturing systems use products from multiple vendors. Companies need a full picture of every component and connection to strengthen their network security. Attackers can manipulate compromised medical devices to deliver incorrect doses that could lead to fatal outcomes.

Pharmaceutical companies must use network segmentation, encrypted communications, and reliable identity management practices..

Automation and 3D Printing in Manufacturing

Advanced manufacturing technologies are accelerating change in the pharmaceutical industry in 2025, with automation and 3D printing at the forefront. The FDA actively encourages companies to adopt these innovations early to improve product quality, speed up development, and enhance operational efficiency.

Continuous manufacturing is replacing traditional batch processing, allowing materials to flow through integrated systems that operate nonstop. At the same time, 3D printing is enabling the creation of customized medications tailored to individual patient needs. Robotics also plays a growing role, especially in sterile environments where precision and contamination control are critical.

Key benefits of these technologies include:

- Reduced need for inventory storage thanks to continuous production

- Real-time data collection for better decision-making

- Faster time-to-market for new drug products

- Personalized medications that lower the risk of side effects

- Improved sterility through robotic systems that limit human involvement

- Safe and efficient manufacturing in environments where human presence is restricted

Conclusion

Pharmaceutical technology is no longer a future promise—it is a present force actively reshaping how drugs are developed, manufactured, and delivered.

The integration of automation, cloud platforms, blockchain systems, and advanced analytics is not only solving long-standing challenges but also creating new opportunities for growth and resilience. These tools enable companies to reduce risks, increase output quality, and respond more swiftly to both regulatory demands and patient needs.

While challenges remain, including data quality requirements and the growing threat of cybersecurity breaches, the momentum behind digital innovation is clear. Organizations that embrace these changes with a strategic mindset will be better equipped to deliver, more than just private label capsules, they will deliver safe, effective, and timely medications in an increasingly complex global landscape.