It is no exaggeration when we say that lasers are revolutionising the medical device sector. Laser processing has indeed opened up a wide range of prospects for manufacturers as well as users, which has led to an upsurge in demand for this technology. As per data from Markets and Markets, the global laser technology market is anticipated to grow at a CAGR hovering around 8.9% from 2022 through 2027 and hit $25.6 billion at the end of the predicted period.

Laser processing technology comes with a wide range of applications and can be used for welding, cutting, as well as marking substances such as metals, composites, and plastics. These processes get carried by pinpointing high energy laser beam components on to the material at speeds that are as much as 10 km/s. The highly focused nature of the laser beams, as well as their ability to heat up specific areas, allow them to cut across materials with minimal damage. This technology can have many applications across the medical laser processing arena. Laser welding is all about combining two metal pieces together until they become molten enough for fusion to take place. The process happens to be much faster than the traditional soldering and brazing method which require to heat both the surfaces evenly much before the fusion occurs.

Laser Processing Applications

It can be used across many industries, such as the medical device industry, and can also be used in the case of making parts for medical devices and other products.

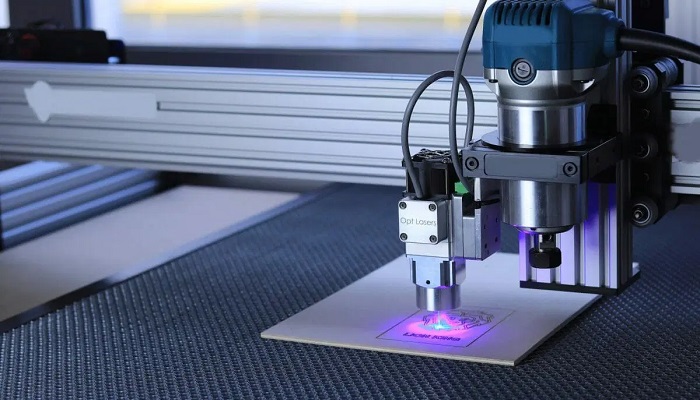

Laser marking happens to be a popular application of laser processing technology. It enables the creation of high-quality and durable marks on the part’s surface, which can be used to identify the point or indicate safety or quality specifications. For instance, if one is making a medical device and wants to ensure that FDA standards are met, it may be a prime requirement to have some sort of mark indicative of this fact on the packaging of the product. One can also make use of coding technology as well as laser marking as part of the assemble line process. Placing different serial numbers on the finished products shall make it much easier for employees who are in charge of shipping the said products, as they will not have to manually look for any individual number prior to sending them.

Laser marking does not have an impact on the corrosion resistance of medical devices. When manufactured using metals, medical devices are always at risk of corrosion, which can further impact patients’ health. Corrosion resistance thereby becomes very vital.

Although there are many who are of the opinion that laser marking can reduce corrosion, that is not the case. As per a study, laser marking does not have an effect on corrosion resistance except if the material happens to be stainless steel. As per the study, the stainless-steel laser marking can make the products less resistant. That said, all other materials do not show any effect of laser marking.

Because of the umpteen benefits it offers, there is an exponential growth that is being witnessed in the laser marking industry. As per a Data Bridge Market Research analysis, the laser marking vertical is expected to increase at a CAGR of 6.8% between 2021 to 2028.

Laser Welding in micro joining for intricate parts

This happens to be an exceptional method when it comes to joining intricate parts like the tiny components in medical devices. Laser welding helps in joining dissimilar materials as well as smaller parts without even melting them, and it is clean, fast, and cost-effective as compared to other methods that are used in joining metal parts.

Quick: A laser has the capability of travelling up to 100 miles in a second, which means that one can fuse two pieces in milliseconds.

Clean: Unlike other processes that create toxic fumes, laser welding produces no harmful gases.

Cost-effective: There are no consumables required for the process, and only electricity is required for execution. It is well to be noted that laser welding has gone on to become a standard application process in the medical device manufacturing sector. This is due to the fact that medical devices are kept clean so as to ensure that there are no adverse effects on the user.

Implantable Devices Laser Cutting

These are parts that are placed inside the human body for certain medical purposes, such as pacemakers, stents, hip replacements, implants, and catheters. These devices have to be durable enough to last for years inside the body without getting damaged due to other fluids or tissue growth around them. They also must be able to withstand a situation where they are needed to be removed for repairs or even replacements over a period of time. The laser beam cutting process enables cutting medical devices with precision, thereby reducing potential damage in the long run.

Surface Structuring with Laser Micromachining

Laser micromachining happens to be a process that creates small features on the surface by eliminating material with the use of a laser beam. It can be used in ways such as inclusion of surface structuring as well as microelectronics. This technique has been around since the 1970s, but it was only recently that it became more widely used due to technological and material advancements that have made it possible for this tool to be more useful than ever.

As of today, medical device manufacturers as well as microelectronics manufacturers make use of laser micromachining as a solution since they require parts that are of high quality with geometries that happen to be complex and would otherwise be complicated or impossible to manufacture by way of traditional methods. Laser surface structuring can help create a wide surface texture range. It is no surprise that laser processing technology has gone on to make a huge impact on the medical device sector. The capacity to weld, mark, cut as well as micromachine delicate parts itself mean that medical devices need to be manufactured by great amount of precision.