Enexor BioEnergy , a U.S. organic waste-to-energy company, has formed Breathe Strong, LLC, committed to the design and manufacturing of the XVENT, a ventilator designed to help with current ventilator shortages during the COVID-19 pandemic, and future pandemics. In less than thirty days, Breathe Strong designed and started manufacturing the XVENT. The XVENT will be manufactured at Enexor’s manufacturing facilities in Franklin, Tennessee, and Huntsville, Alabama, with a capacity to produce up to 200 units per day.

Additionally, the XVENT will be manufactured in other countries to address their medical device shortages, mitigating the financial burden associated with full-featured ventilators. Breathe Strong will be donating the XVENT to Ghana, the Dominican Republic, Panama, and other countries, as soon as export permission is granted. On April 11, 2020, Breathe Strong submitted a request for Emergency Use Authorization (EUA) by the FDA and will submit for final FDA approval in June.

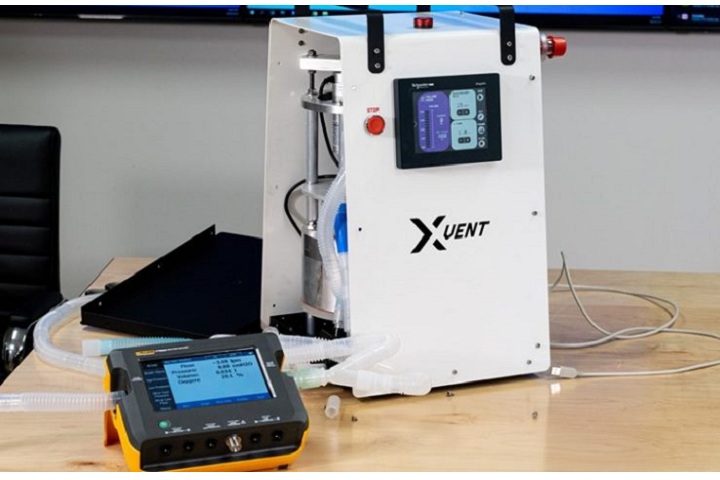

The XVENT is a continuous, positive pressure ventilator that is capable of assisting a patient with respiratory insufficiency or respiratory failure. The XVENT utilizes a precision machined piston system controlled by an industrial-grade programmable logic computer (PLC). The system is self-calibrating, equipped with back-up battery power, and designed for many years of use. Qualified medical professionals can control and remotely monitor pressure, volume, inspiratory time, and respiratory ratio to provide life-sustaining ventilatory assistance.

“Less than a month ago, a doctor partner of ours in a developing country reached out to me looking for ventilators. I asked him how many he needed. He answered, ‘one ventilator saves two lives; you do the math,’” said Lee Jestings, founder and CEO of Enexor.

“That evening, I challenged my team to design and build a ventilator that is reliable, affordable, and deployable in any remote hospital around the world. The Enexor team, led by Scott Auerbach, Director of Engineering, quickly went to work, and delivered within three weeks.”

“We immediately made some important design decisions. First, we would not use a bag valve mask (BVM) resuscitator but instead would use a precision machined piston air pumping system. Second, we would design with industrial-grade programmable controllers and electronics. Third, we would design a ventilator with the intent of getting full FDA approval; and finally, the ventilator must be competitive in function, but affordable,” said Scott Auerbach.

Immediately, Breathe Strong put together an advisory team of medical professionals consisting of critical care physicians and current respiratory therapists to define ideal modes, features, performance, and operating parameters. They then reached out to several companies that could assist with the initiative. What emerged was a world-class team of Tennessee companies and consultants from Maine to Oregon.

“The user’s ability to control the XVENT is our design’s most critical component. So we immediately reached out to Schneider Electric (www.se.com), Casco Systems, and Border States Electric (www.borderstates.com). These companies are the gold standard for designing, producing, and distributing the best industrial controls components on the market.”

Breathe Strong’s local Tennessee neighbors also responded immediately. Wolfe Industrial in LaVergne, John W. McDougall Co. in Nashville, and Ironcraft Inc. in Lewisburg worked nights and weekends to support us with high-quality steel parts and components. Nemo Design, a Portland, Oregon based brand-design agency, volunteered their time to provide expert product-design, branding and marketing support.